Identification Solutions for Industrial Applications

InfoSight offers fully automated industrial marking solutions to accommodate a wide variety of applications, including billets, blooms, and slabs. From red-hot steel plates, coils, and long products to tubes and pipes, InfoSight’s durable identification solutions remain readable even when products are stacked, shifted, and bundled together in the production process. By automating the identification process, you can increase the productivity of your operations, remove the risk of human error, and ensure the safety of your employees.

Automated Marking Systems

Automated systems that identify in-process products are more efficient, accurate, and safe. InfoSight’s marking systems are fully automatic and programmable, and they can be easily integrated with other technologies, including robotics. They have high operating speeds and printing capacities, providing significant labor savings and risk reductions for your operation. These rugged and reliable machines are built for the most severe industrial environments, and they are specially designed for easy maintenance.

Dot Peen Stamp Marking

Heavy-duty industrial dot peen marking systems from InfoSight create permanent, indented marks for long-term product traceability. They can print alphanumeric characters and 2D barcodes on scaly, rough, curved, irregular, or uneven surfaces, making them perfect for castings, billets, blooms, slabs, plates, and pipes.

Stencil Marking

Automated ink stencil marking is a safer, more cost-effective alternative to manually stenciling products in industrial environments. Each of InfoSight’s spray marking systems, including our fully automated weigh-measure-stencil system, offer superior readability and durability in hot and ambient conditions. Available markings include barcodes and a full range of alphanumeric characters in a wide array of fonts for machine-readable identification.

Laser Marking

Our high-contrast laser marking systems operate by marking a white patch of ink that can be applied to a variety of surfaces. The resulting barcodes are sharp and machine-readable, as well as highly resistant to subsequent manufacturing processes. InfoSight’s laser marking systems operate in a variety of industries, including automotive, steel pipe, and manufacturing.

Automated Tagging Systems

We offer automated systems to apply high-quality tags to a variety of products. Tags can be applied to assets such as hot slabs, billets, and coils by welding or nailing, via traditional or robotic automation. Our systems can be designed for a variety of tagging options.

Interested in our marking technologies?

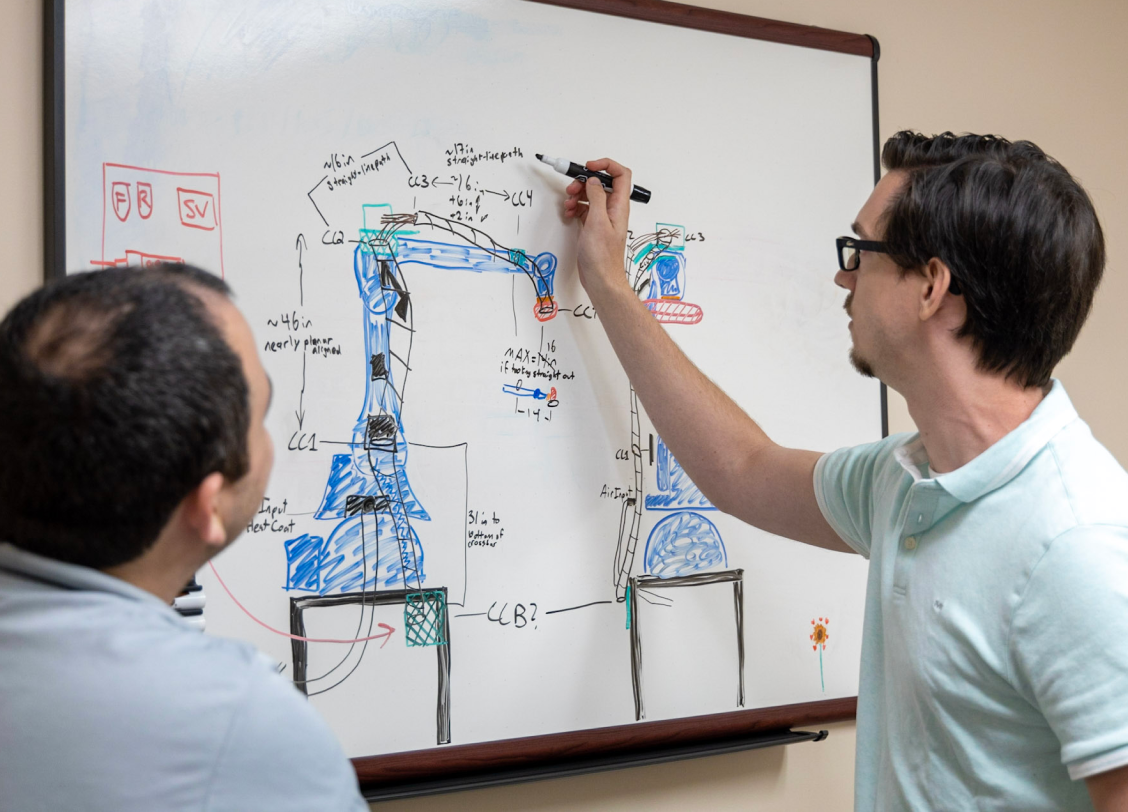

Automated Design

InfoSight integrates our marking technologies into systems that are custom designed for each facility. We take into consideration available floor space, production rate, and other requirements when designing our marking systems.

Robotic Automation

We can integrate any of our marking technologies onto a robot, providing custom automated marking systems with small footprints and quick cycle times.

Traditional Automation

Automated systems from InfoSight reduce labor hours by streamlining the identification of all your assets. Our traditional machines use hard automation to create an identification mark on products and assets like hot steel slabs, billets, blooms, plates, and coils.

Moving or Stationary Products

Each production process is unique and therefore requires a unique identification solution. Systems from InfoSight can be configured with different marking technologies in order to best match the application requirement, marking both moving and stationary products like pipes and tubes.

Hot or Cold Products

InfoSight’s automated systems can mark products at extremely high temperatures as well as ambient temperatures. Very hot applications present a unique challenge, which we address by using system cooling and heat shields and by customizing the marking technology and materials to the requirement.

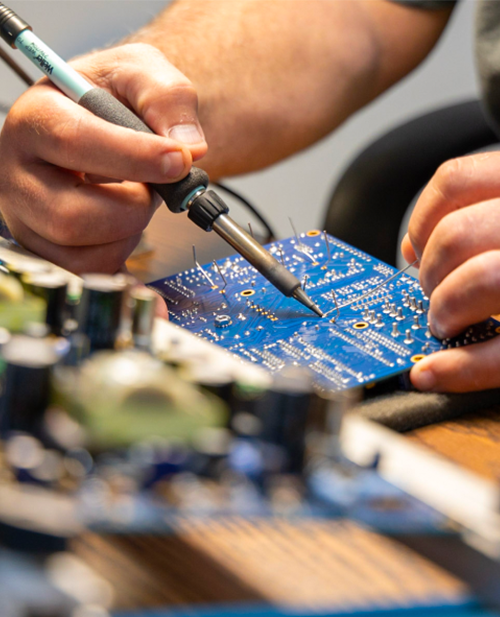

Design & Build

Process Automation Resources

Don’t see a solution for your business?

Our team of scientists and engineers will work to understand your challenge, then we’ll test, experiment, and invent to provide the best possible solution.