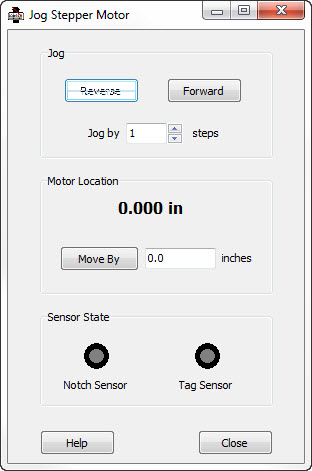

Jog Motor

The Jog Stepper Motor dialog is useful for exercising the printer’s stepper motor. With this dialog, you can:

Jog the motor by single (or multiple) steps in either the forward or reverse directions.

Specify a specific position relative to the notch sensor and have the motor move there.

Monitor the state of the notch and tag sensors to determine if the sensors are functioning properly.

Reverse - This button will cause the motor to move in the reverse direction by the number of steps specified in the Jog By field.

Forward - This button will cause the motor to move in the forward direction by the number of steps specified in the Jog By field.

Jog By - This field allows you to specify the number of steps to move when jogging in either the reverse or forward direction.

Motor Location - This entry field display the current tag material position, which is the distance moved past the notch sensor. You may

enter a new number here and press the Move By button, which will cause the motor to move to the indicated position.

Move By- This button is used in conjunction with the Motor Location to move the motor / tag material to a specific position relative to

the notch sensor.

Notch Sensor - This is an indicator of the state of the notch sensor. When the notch is at the sensor, the indicator will glow yellow.

Tag Sensor - This is an indicator of the state of the tag sensor.

|