Selecting the right metal identification tag for industrial applications is crucial for ensuring efficient traceability, compliance, and inventory management. Whether you work in steel manufacturing, galvanizing, fabrication, or logistics, the right tag ensures materials remain properly identified through even the harshest conditions. On the other hand, choosing the wrong tag can lead to misidentification, compliance issues, and costly operational inefficiencies.

At InfoSight, we specialize in durable tagging solutions tailored to various environments. This guide will help you understand the different types of industrial tags and how to choose the best one for your needs.

Why Industrial Tags Matter

Industrial tags play a crucial role in traceability, inventory management, compliance, and quality control. They help track materials from production to final use, ensuring accurate records and reducing errors in handling. The right tag ensures that materials are identified correctly, preventing costly mistakes and maintaining compliance with regulatory standards.

Because different industries have unique tagging requirements, multiple factors must be considered when selecting a tag, including heat resistance, chemical exposure, abrasion resistance, and durability. Selecting a tag that matches your environment will ensure long-term legibility and reliability.

Types of Industrial Tags

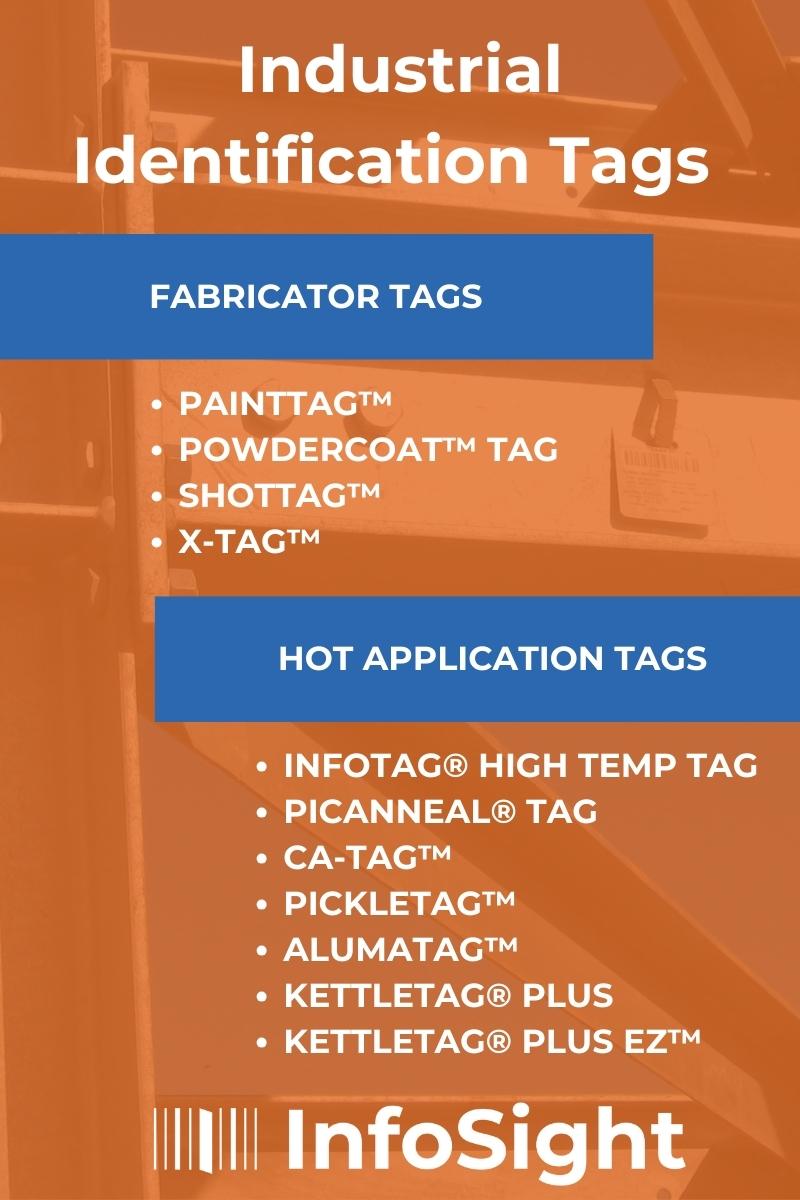

InfoSight offers a variety of industrial tags designed for different environments and applications. These tags fall into two main categories: Fabricator Tags (Best for general manufacturing, fabrication, and coating processes) and Hot Application Tags (Best for steel mills, galvanizing, and high-heat environments).

InfoSight’s line up of Fabricator Tags include:

- PaintTag™

- PowderCoat™ TAG

- ShotTag™

- X-Tag™

Fabricator tags are designed for industries where identification is required before, during, and after finishing processes like painting, powder coating, and shot blasting. These tags resist exposure to chemicals, coatings, and mechanical abrasion while maintaining their legibility. Whether surviving a high-temperature curing oven or a shot-blasting process, these tags ensure that critical identification remains intact.

Hot Application Tags include:

- InfoTag® High Temp Tag

- PicAnneal® Tag

- CA-Tag™

- PickleTag™

- AlumaTag™

- KettleTag® Plus

- KettleTag® Plus EZ ™

Hot application tags are built to withstand extreme temperatures, molten metal exposure, and chemical treatments. Whether tags are immersed in acid pickling baths or exposed to high heat during galvanizing, they remain legible and attached. These tags ensure compliance with traceability requirements in harsh processing conditions.

How to Choose the Right Tag

Selecting the best tag for your application involves considering several key factors to ensure optimal performance and durability. Follow these steps to make an informed decision:

- Asses Environmental Conditions

- Identify Application Needs

- Evaluate Compliance Requirements

- Select a Printing or Marking Method

Assess Environmental Conditions

Start by determining the environmental conditions the tag will face. Will it be exposed to extreme temperatures, chemicals, moisture, or physical stress? Tags used in harsh environments, like steel mills or galvanization processes, need to withstand significant wear and tear. Factors such as high heat, corrosive substances, and abrasion can affect the longevity and legibility of a tag.

For example, a tag used in a galvanization kettle needs to resist high heat and exposure to chemicals like zinc, which can deteriorate standard materials quickly. Consider the climate, exposure to outdoor elements, and whether the tag will be subjected to direct contact with machinery or other heavy-duty applications.

Identify Application Needs

Consider the purpose of the tag: Is it for permanent or temporary identification? Permanent tags should be durable and resistant to fading over time, while temporary tags might need to be easily removed or replaced. Determine how the tag will be read—whether by human operators, scanners, or other automated systems. Also, think about the visibility requirements: Will the tag need to stay readable after being subjected to processes such as cutting, welding, or coating? Tags for manufacturing environments must maintain legibility despite exposure to high temperatures, heavy wear, and chemical treatments. Choosing a tag that meets these needs is crucial for ensuring accurate identification throughout the product’s lifecycle.

Evaluate Compliance Requirements

Certain industries are governed by strict regulatory standards that dictate tagging requirements. Before selecting a tag, verify whether your industry has any relevant regulations, such as OSHA or ISO standards, that require specific traceability methods. Some industries require tags to ensure traceability for safety reasons, while others mandate specific labeling for compliance with environmental, quality control, or safety guidelines. Knowing these requirements upfront will prevent delays or compliance issues and ensure your tags meet all necessary standards.

Select a Printing or Marking Method

Finally, choose the right printing or marking method for your tags. Various techniques, such as laser etching, thermal transfer printing, and ink-based marking, offer different advantages in terms of durability and legibility. Laser etching is ideal for high-contrast, permanent markings that are resistant to wear. Thermal transfer printing provides a durable, smudge-free print that is ideal for tags that will be exposed to high temperatures or chemicals.

Ink-based marking can be effective for short-term or temporary applications but may fade over time or under extreme conditions. InfoSight offers a range of solutions that ensure high-contrast, long-lasting identification tailored to your application needs. Whether you require a solution that withstands high heat in a steel mill or a system that resists chemical exposure in petrochemical facilities, InfoSight’s tags are designed to perform in even the most demanding environments.

Industries That Benefit from InfoSight Tags

- Steel Mills & Foundries

- Galvanizing & Metal Coating

- Fabrication & Manufacturing

- Automotive & Aerospace

- Logistics & Supply Chain

- And more!

InfoSight tags are used across these industries to ensure durable and reliable identification. Whether tracking steel coils through production or maintaining traceability through harsh finishing processes, these tags provide a solution that meets your industry’s unique challenges.

Start the Conversation with InfoSight Today!

Not sure which tag is right for your application? Contact your local InfoSight sales rep for a consultation or request sample tags to see how they perform in your environment.

To learn more about our tagging solutions tailored to your industry, complete the contact from below!